Simple Guide to Testing Electric Motors

First Steps: Look and Check

Before you test any electric motor, you need to check it carefully with your eyes and hands. Think of it like giving your car a quick check before a long drive. Here’s what to do:

- Safety First

- Turn off all power to the motor

- Make sure no one can turn it on by accident

- Put on safety glasses and rubber gloves

- Keep a fire extinguisher nearby just in case

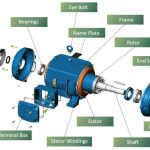

- Look at the Outside

- Check if the motor looks damaged

- Look for dirt and rust

- Make sure no wires are broken or worn out

- Check if all bolts are tight

- Simple Physical Checks

- Try turning the shaft by hand – it should move smoothly

- Look at the bearings – they should have enough oil

- Make sure the cooling fan isn’t blocked

- Check if all parts are tightly connected

- Write Everything Down

- Copy down the motor’s information plate

- Note any damage you see

- Write down any strange noises or smells

- Record the room temperature

- Note when the motor was last fixed

Testing the Motor’s Electrical Parts

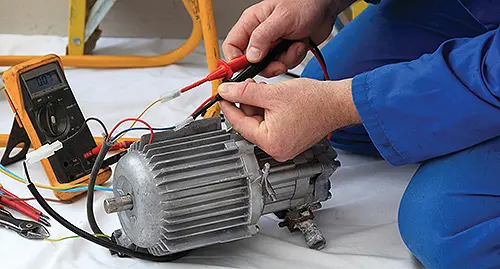

- Testing the Insulation

This test (called a Megger test) checks if the motor’s insulation is good:

- Unplug all wires

- Connect special test equipment

- Take readings after 30 and 60 seconds

- The numbers should be above certain levels depending on your motor’s size

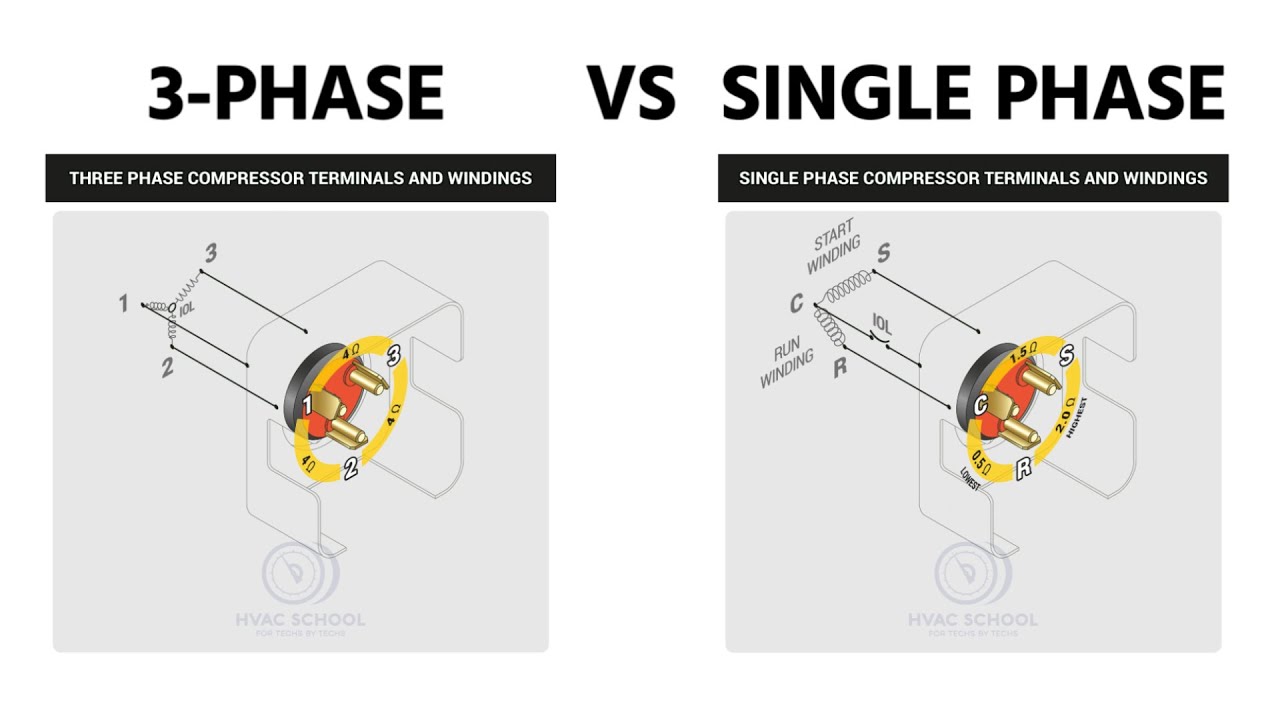

- Testing the Windings

- Measure the electrical resistance in each part

- All measurements should be very close to each other

- If they’re different, something might be wrong

- Special Tests

Some tests need special equipment and trained people:

- Surge testing checks for internal damage

- This helps find problems you can’t see from outside

Running the Motor

- Testing Without Load

First, run the motor without connecting it to anything:

- Check how much power it uses

- Make sure it spins the right way

- Listen for strange noises

- Check if it vibrates too much

- Measure how fast it spins

- Testing With Load

Then test the motor doing actual work:

- Start with a light load

- Slowly increase the work

- Check power use

- Watch the temperature

- Look for vibrations

- Write down all measurements

Checking for Problems

- Look for Vibrations

- Use special tools to measure shaking

- Check if bearings are good

- Make sure everything is lined up right

- Look for loose parts

- Temperature Checks

Use special cameras to:

- Find hot spots

- Check if cooling is working

- Look for overheated parts

- Keep Track of Everything

- Write down all test results

- Compare new tests with old ones

- Plan when to do maintenance

- Fix small problems before they get big

Remember:

- Always be safe

- Use the right tools

- Keep good records

- Fix problems when you find them

- Test regularly to prevent breakdowns

Testing motors isn’t hard if you follow these steps carefully. Regular testing helps catch problems early and keeps your motors running well for a long time.