How to test a electrical motor with klein mm700

Testing Motors the Easy Way with a Klein MM700

Electric motors are important parts that run machines. To keep motors working well, you should check them regularly. This guide shows how to test basic motor health and function using a Klein MM700 multimeter.

About the Multimeter

The Klein MM700 is a good choice for motor testing. It can measure lots of things and has a big screen. It checks voltages and currents running through wires very accurately. It is also very durable and safe to use on high voltages, which is important when testing motors.

What You Can Test

As well as checking wiring for breaks and continuity, the MM700 can inspect motor windings. It can monitor voltages and currents without interfering with motor operation. The logging feature records how readings change over time. All together, these basic tests help make sure motors keep running properly.

Getting Ready

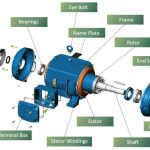

First, disconnect the motor from power sources and lock switches off. Look for any damage or overheating. Note important details listed on nameplates. Label each motor wire clearly based on diagrams.

Set up the MM700 using the right measurement ranges. Check test leads and that it works properly. Always be careful of electrical safety. Now the testing can start!

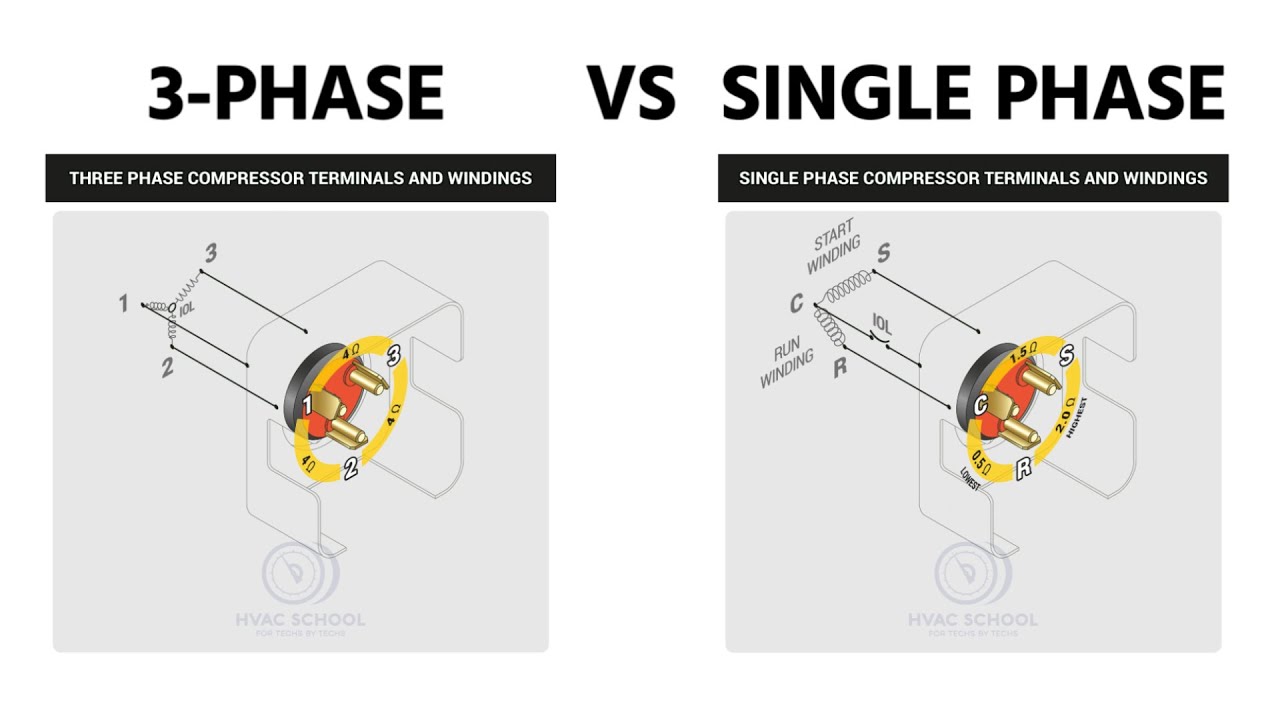

Checking the Windings

Motor windings need to work right for performance and lifespan. Measure winding resistance between wire pairs using ohms (Ω). Results should match nameplates, give or take 10-20%. Big differences may mean loose wires, heating issues or breaks. Record readings to monitor over time.

Operational Tests

For an on motor, switch to volts and amps. Voltage supplied should equal voltage read. Current shows load amount – big changes could signal trouble. Logging watches for changes signaling weak parts. Abnormal values help diagnose issues.

Common Problems

The MM700 helps technicians quickly figure out if motors need repair or replacement. High/low readings point to specific issues, like faulty connections or grounding risks. With practice, basic but informative tests keep motors in good shape.