The Siemens 1FP1014-0DB2 is a high-performance servo motor, Let’s explore everything you need to know about this motor in simple terms.

What is a Servo Motor?

Before we dive into the details, let’s understand what makes a servo motor special:

- It’s like a super-accurate electric motor

- Can make very precise movements

- Knows exactly where it is at all times

- Can be controlled very carefully

- Works well with computers and automation

Basic Features of the 1FP1014-0DB2

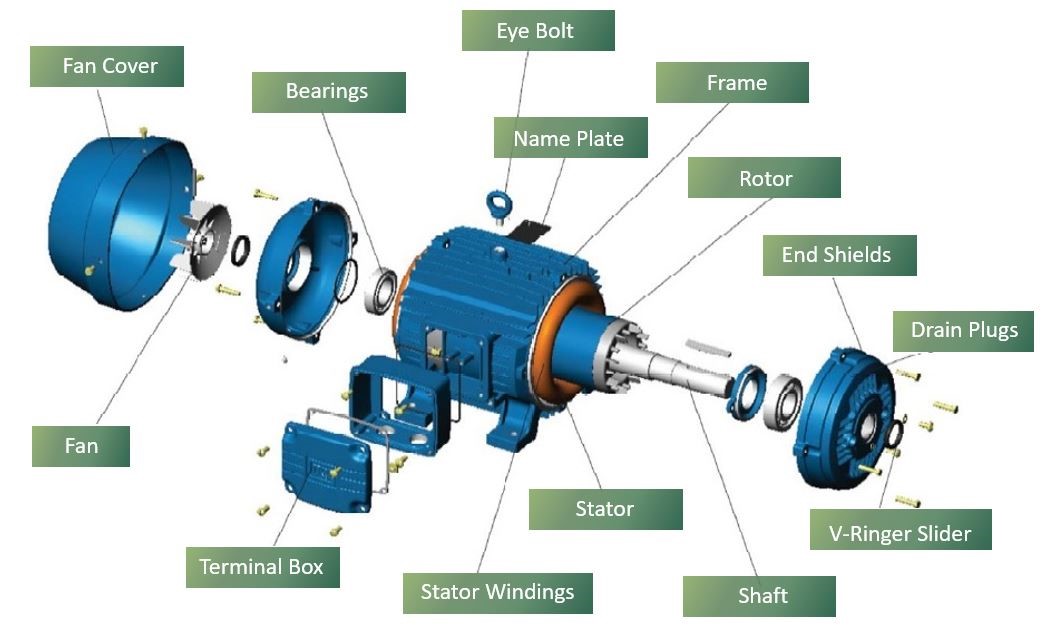

- Physical Features

- Compact size for easy installation

- Durable metal construction

- Built-in feedback system

- Precision bearings

- High-quality connections

- Performance Features

- Quick response time

- Accurate positioning

- Smooth movement

- High torque (turning power)

- Good speed control

- Control Features

- Digital control system

- Position feedback

- Speed monitoring

- Temperature sensing

- Error detection

Where Can You Use This Motor?

- Manufacturing

- Assembly lines

- Packaging machines

- Pick and place robots

- CNC machines

- Precision tools

- Automation

- Robotic systems

- Conveyor controls

- Sorting machines

- Testing equipment

- Quality control systems

- Special Applications

- Medical equipment

- Lab instruments

- Printing machines

- Camera systems

- Positioning tables

Installation Guide

- Before Installation

Prepare for success:

- Check the motor condition

- Gather necessary tools

- Read the manual

- Plan the mounting location

- Verify power requirements

- Installation Steps

Follow these steps carefully:

a) Mounting

- Choose a solid surface

- Align properly

- Use correct bolts

- Check for level mounting

- Ensure proper ventilation

b) Wiring

- Follow the wiring diagram

- Use proper cables

- Make secure connections

- Check grounding

- Verify all connections

c) Setup

- Configure the drive

- Set parameters

- Test basic functions

- Check feedback

- Verify safety systems

Operating the Motor

- Basic Operation

Getting started:

- Power-up sequence

- Initial checks

- Basic movements

- Speed control

- Position control

- Advanced Functions

More complex operations:

- Programming movements

- Setting up sequences

- Configuring limits

- Tuning performance

- Optimizing control

- Safety Features

Important protections:

- Emergency stop

- Overload protection

- Temperature monitoring

- Position limits

- Error detection

Maintenance Guide

- Regular Checks

Daily/weekly tasks:

- Visual inspection

- Noise monitoring

- Temperature check

- Movement tests

- Connection inspection

- Periodic Maintenance

Monthly/yearly tasks:

- Cleaning

- Bearing check

- Cable inspection

- Parameter verification

- Performance testing

- Preventive Care

Avoiding problems:

- Keep area clean

- Monitor performance

- Record unusual events

- Check alignments

- Update software

Troubleshooting Common Issues

- Motor Problems

Common issues:

- Won’t start

- Unusual noise

- Vibration

- Overheating

- Position errors

- Control Problems

System issues:

- Poor response

- Positioning errors

- Speed variations

- Communication errors

- Parameter problems

- Solutions

How to fix things:

- Check connections

- Verify settings

- Test components

- Update software

- Call support when needed

Optimizing Performance

- Basic Optimization

Simple improvements:

- Clean regularly

- Check alignment

- Update parameters

- Monitor feedback

- Keep records

- Advanced Optimization

Better performance:

- Fine-tune controls

- Optimize movements

- Improve accuracy

- Reduce cycle times

- Save energy

Safety Guidelines

- General Safety

Basic rules:

- Follow procedures

- Use proper tools

- Wear safety gear

- Keep area clean

- Train properly

- Electrical Safety

Working with power:

- Disconnect power

- Use proper tools

- Check grounding

- Follow lockout procedures

- Test before touching

- Operational Safety

Safe operation:

- Know emergency stops

- Understand limits

- Monitor operation

- Report problems

- Keep records

Integration with Systems

- Control Systems

Working with controllers:

- PLC connections

- Computer control

- Network setup

- Programming

- Monitoring

- Feedback Systems

Using feedback:

- Position sensing

- Speed monitoring

- Error detection

- Performance tracking

- Quality control

Cost Considerations

- Operating Costs

Regular expenses:

- Power consumption

- Routine maintenance

- Regular inspections

- Minor repairs

- Software updates

- Long-term Costs

Future planning:

- Major maintenance

- Upgrades

- Replacement parts

- Training

- System improvements

Environmental Factors

- Operating Environment

Important conditions:

- Temperature

- Humidity

- Dust levels

- Vibration

- Air quality

- Environmental Impact

Being eco-friendly:

- Energy efficiency

- Waste reduction

- Proper disposal

- Resource conservation

- Sustainable practices

Technical Support

- Getting Help

Where to find support:

- Siemens service

- Local distributors

- Online resources

- Technical forums

- Training programs

- Documentation

Important papers:

- User manual

- Installation guide

- Maintenance records

- Performance data

- Service history

Future Considerations

- Upgrades

Possible improvements:

- New features

- Better control

- Updated software

- Enhanced safety

- Improved efficiency

- System Evolution

Planning ahead:

- Technology changes

- New requirements

- System expansion

- Performance needs

- Cost reduction

Best Practices

- Operation

Daily use:

- Follow procedures

- Monitor performance

- Keep records

- Train users

- Maintain cleanliness

- Maintenance

Regular care:

- Schedule checks

- Preventive maintenance

- Keep spares

- Document everything

- Update training

- Management

System oversight:

- Track performance

- Plan improvements

- Budget properly

- Train staff

- Update procedures

Success Tips

- Installation Success

Getting started right:

- Proper planning

- Careful installation

- Correct setup

- Good testing

- Complete documentation

- Operation Success

Running well:

- Regular monitoring

- Quick response to issues

- Good maintenance

- Proper training

- Clear procedures

- Long-term Success

Staying successful:

- Continuous improvement

- Regular updates

- Good records

- Staff training

- Forward planning

Conclusion

The Siemens 1FP1014-0DB2 is a powerful and precise servo motor that can make a big difference in your automation systems. Remember these key points:

- Installation

- Plan carefully

- Install properly

- Set up correctly

- Test thoroughly

- Document everything

- Operation

- Monitor regularly

- Maintain properly

- Respond to issues

- Keep records

- Train users

- Maintenance

- Regular checks

- Preventive care

- Quick repairs

- Good documentation

- Proper training

- Future Planning

- Watch for updates

- Plan improvements

- Budget properly

- Train staff

- Keep learning

With proper care and attention, this motor will:

- Work reliably

- Last longer

- Perform better

- Cost less to operate

- Help your business succeed

Remember:

- Safety first

- Follow procedures

- Keep learning

- Plan ahead

- Ask for help when needed

This motor represents Siemens’ commitment to quality and innovation in automation. Whether you’re using it in manufacturing, medical equipment, or other precision applications, it’s designed to provide reliable, accurate service while maintaining high performance standards. With proper care and attention, it will be a valuable part of your automation system for many years to come.